Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

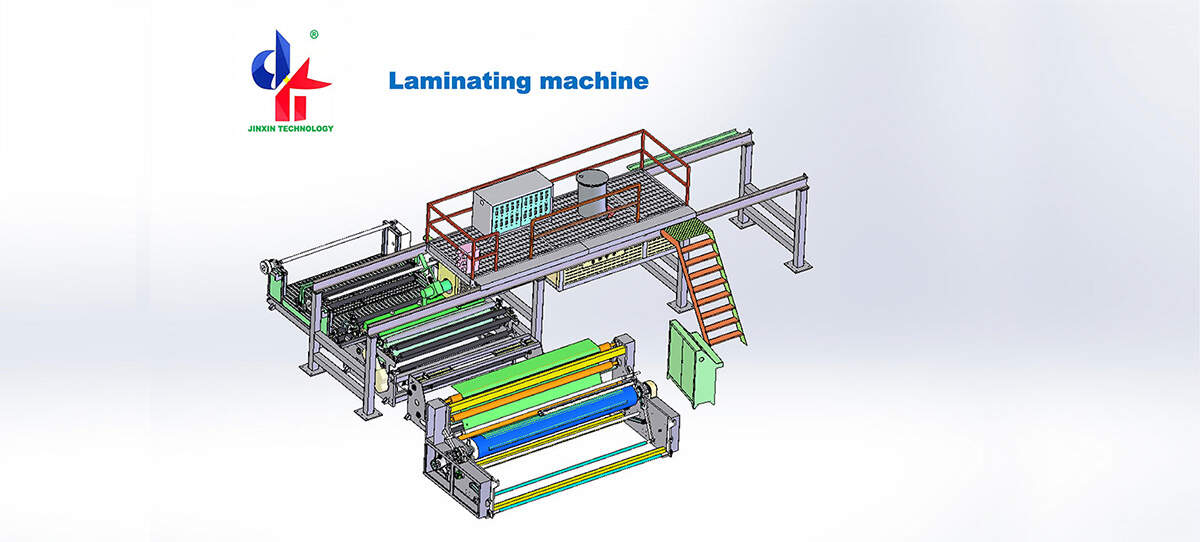

Best Price Nonwoven Roll Lamination Coating Machine Manufacturer

This extrusion laminating machine processes by melting the plastic to extrude from the T-die mould and then laminating with the base material. This type of machine has been widely utilised for the lamination of substrates such as paper, non-woven fabric, woven fabric, aluminium foil, BOPP film, etc. The final product is renowned for its excellent fastness, thickness homogeneity, and strong sealing ability.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Product Description

This extrusion laminating machine uses resin, such as LDPE, HDPE, PP, EVA, etc., as raw material, it processes by melting the plastic for extruding from the T-die mold and finally laminating with the base material, this type of machine has been widely used for the lamination of substrates such as paper, non-woven fabric, woven fabric, aluminum foil, BOPP film, etc. the finished product is famous for its high fastness, uniformity of thickness and high sealed capability. All these have contributed of make this type of machine become one of the most popular and valuable extrusion laminating machines in the domestic market and abroad.

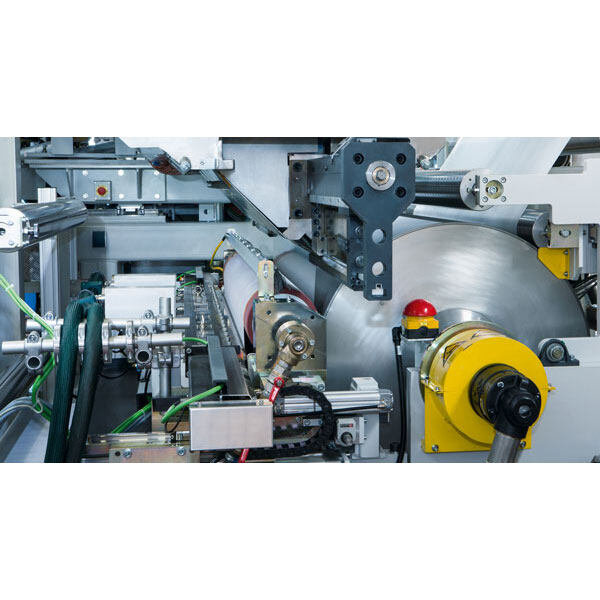

Machine composition

Double Feeding Part

Function: Automatic loading, magnetic power tension controller, Automatic correcting deviation system.

Correcting deviation device

Ensure the accuracy of double layer lamination.

Corona Equipment

Adopts dustproof,interference-proof structure, pneumatic switch cover equipment, achieve discharging ozone.

Extrusion Equipment

Car type extrusion machine.

T-type die head.

Automatic PE feeding equipment.

Oil hydraulic pump changes filter Aromatically.

Second Feeding equipment

360-degree feeding frame.

High tension control accuracy.

Double Air shaft.

Extrusion and compounding equipment

Three roller compounding mechanism.

Peeling off silicone roller.

A high-pressure blower sucks scrap edge quickly.

Rewinding equipment adopts a cylinder to switch automatically.

Drove by one vector frequency electric motor.

Rewinding equipment

(1) Surface rewinding (Double work-station,Non-stopping).

(2) Surface rewinding roller is driven independently.

(3) Drive motor.

(4) Frequency speed control.

(5) Rewinding shaft be pressed by competing cylinder.

(6) Hydraulic pressure edge regulating.

Control unit

(1) Frequency control of motor speed.

(2) Rewinding shaft air clamper.

(3) Other equipment.

(4) The rack adopts the wallboard structure.

(5) Pneumatic: all are of excellent quality, and the gas circuit can be controlled with the first touch.

(6) Automatic mechanical transmission system.